What is an Electric motor?

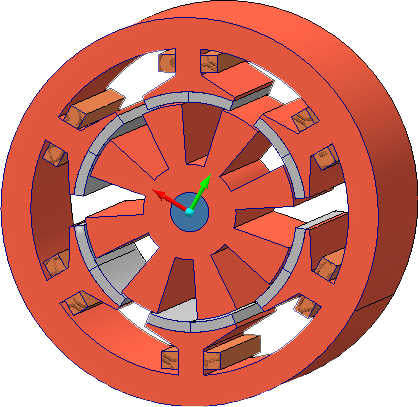

Electric motor is an electrical machine which converting electrical energy into mechanical motion. The two mechanical component of electric motor are Stator which is fixed and rotor which moves. It also has two electrical component which is magnet set attached to the rotor and winding attached to the stator together making magnetic circuit. Electric motors operate through the interaction between the magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. Motor

The best way to design the high efficiency motor is by using Electromagnetic software tools. The procedure described here can be applied to both AC motors and DC motors.

We follow these 5 steps to design the efficient motor for various applications:

Step 1

• Define electric motor requirement in terms of voltage, power, speed-torque characteristics and load profile and dimensions of motor.

Step 2

• Selection of Motor types and winding pattern based on the customer application requirement. The winding technology has a great influence on the electric motor design.

Step 3

• Sizing of the motor based on the given power requirement. We mostly look at what dimension used other manufacturers and competitors who have similar requirements.

Step 4

• Analytical motor design calculation using some analytical software tool or excel sheet defined calculation for slotted and slot less motors. We use analytical tool for calculate the torque and power by giving input parameters like diameter, length and voltage of the electric motor. However, in analytical calculation the accuracy is usually between 70 to 80 percent. It depends on the complexity of the electric motor and the software used.

Step 5

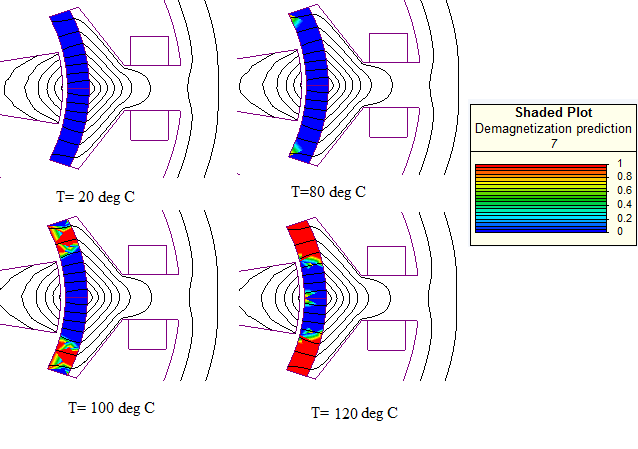

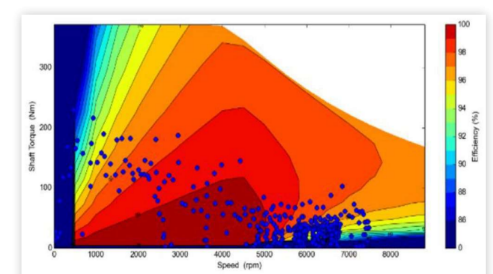

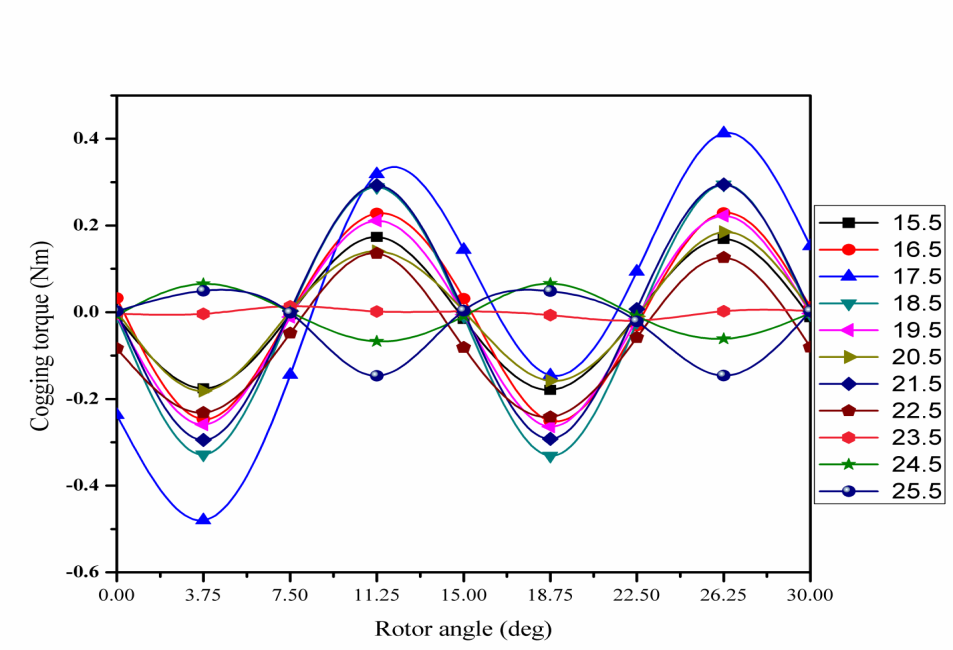

• 2D/3D FEM Electric Motor Simulation: By using Finite element tool we provide the accurate solution for the motor. Using those tools we do detailed Electromagnetic analysis like, Flux pattern, Back EMF analysis, Torque-speed characteristics, efficiency mapping, cogging analysis, demagnetization study, optimization of motor, sensitivity study based on customer requirement.

What We Do?

VcreateGearedMotors is specialized in consulting and creating designs for mechanical gearboxes used in various machines and equipment.

We are responsible for designing gear arrangements, determining gear ratios, selecting appropriate materials, and ensuring that the gearbox meets the required specifications and performance criteria.

Additionally, we also conduct stress and load analyses, optimizing gear geometry, and providing technical guidance to manufacturers during the production process.

Why choose VcreateGearedMotors?

Our team of motor and gearbox design consultants has more than a decade of experience in the industry and have successfully designed a wide range of motors and gearboxes for various applications.

Overall, we are committed to providing top-notch motor design consultancy services that are reliable, efficient, and tailored to your specific needs. Choose us for your next motor/gearbox design project and experience the difference firsthand.

Helix Framework