What is a gearbox?

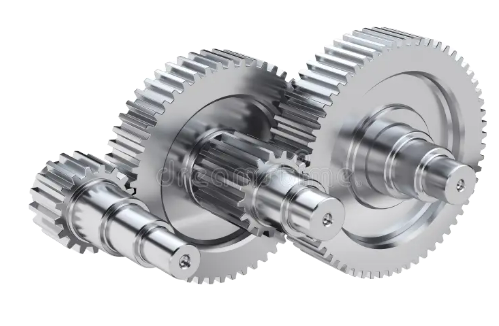

A gearbox is a mechanical device that is used to increase the output torque or change the speed (RPM) of the motor.

Gearboxes, also commonly called gear reducers or enclosed speed reducers are used on many electromechanical drive systems. Gearboxes are essentially multiple open gear sets contained in a housing. The housing supports bearings and shafts, holds in lubricants, and protects the components from surrounding conditions.

Gearboxes are used in many applications, including machine tools, industrial equipment, conveyor belts, and almost any power transmission application with rotary motion that requires a change in torque and speed.

Why do we

need a gearbox?

Motor alone has limited capacity when transmitting high torque and power. We need a gearbox to enhance motor’s capacity to perform and sustain at higher torque.

Overall, a gearbox is essential for optimizing the performance, efficiency, and durability of a motor in various applications like industrial power tools, medical infusion pumps, A&D, surgical motion solutions, Robotics and others.

A gearbox is necessary to be used with a motor for several reasons:

Speed and torque conversion:

A gearbox allows the motor to operate at its optimal speed and torque levels by changing the output speed and torque ratio as needed for a specific application. This is important for ensuring the motor can efficiently drive the load it is connected to.

Mechanical advantage:

A gearbox can provide a mechanical advantage by increasing or decreasing the output speed and torque compared to the motor's input speed and torque. This allows the motor to generate more power or achieve higher speeds than it would be able to on its own.

Control and flexibility:

By using a gearbox, the operator can have greater control over the speed and torque of the motor, making it adaptable to a wide range of applications. This flexibility is essential for various industrial processes and machinery.

Durability and longevity:

A gearbox helps to reduce the wear and tear on the motor by allowing it to operate within its optimal speed and torque ranges. This can extend the lifespan of the motor and reduce maintenance and repair costs in the long run.

What We Do?

VcreateGearedMotors is specialized in consulting and creating designs for mechanical gearboxes used in various machines and equipment.

We are responsible for designing gear arrangements, determining gear ratios, selecting appropriate materials, and ensuring that the gearbox meets the required specifications and performance criteria.

Additionally, we also conduct stress and load analyses, optimizing gear geometry, and providing technical guidance to manufacturers during the production process.

Why choose VcreateGearedMotors?

Our team of motor and gearbox design consultants has more than a decade of experience in the industry and have successfully designed a wide range of motors and gearboxes for various applications.

Overall, we are committed to providing top-notch motor design consultancy services that are reliable, efficient, and tailored to your specific needs. Choose us for your next motor/gearbox design project and experience the difference firsthand.

Helix Framework